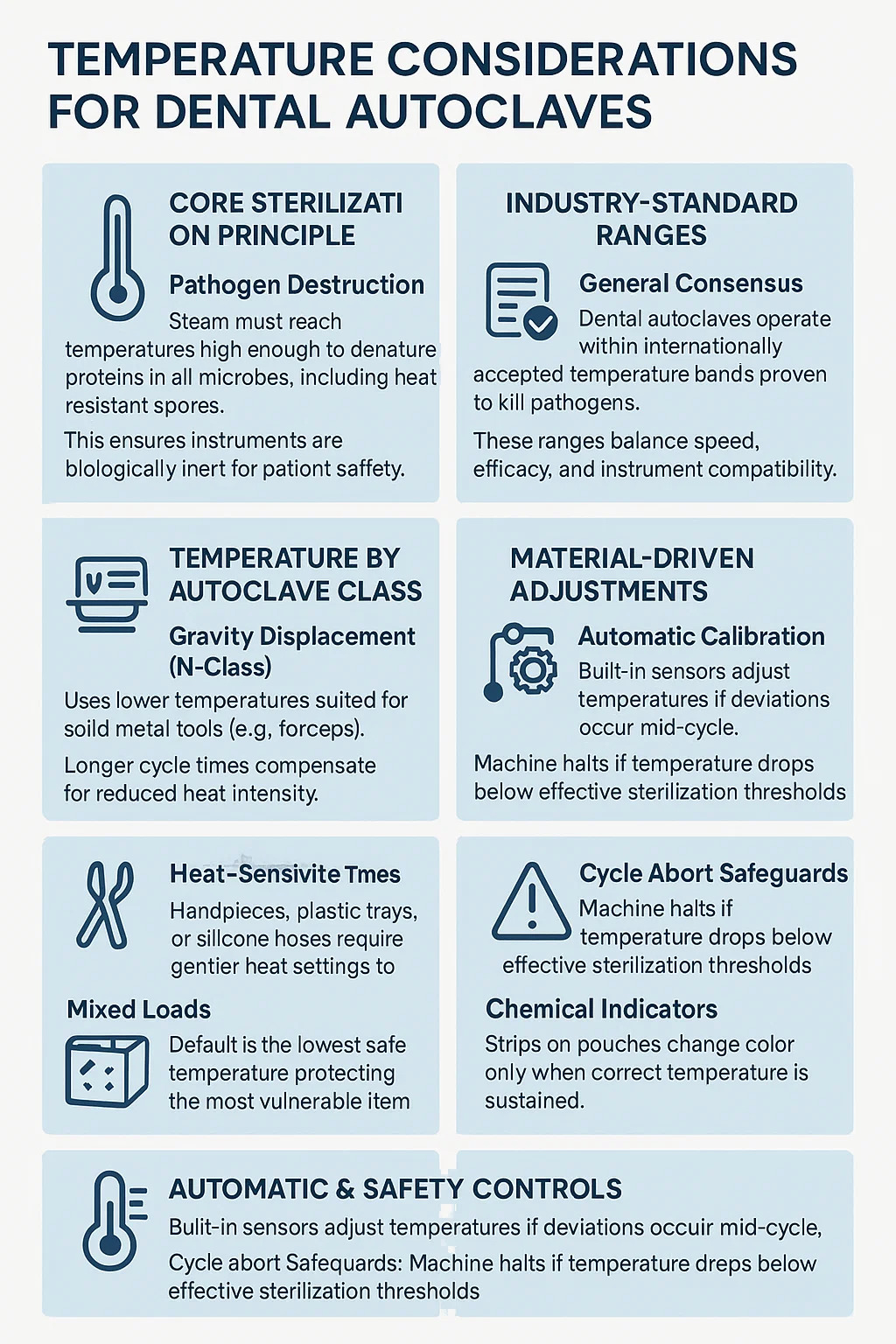

Here's a breakdown of temperature considerations for dental autoclaves:

Content

Pathogen Destruction:

Steam must reach temperatures high enough to denature proteins in all microbes, including heat-resistant spores.

This ensures instruments are biologically inert for patient safety.

Pressure Dependency:

Temperature effectiveness is tied to steam pressure; higher pressure enables higher temperatures.

General Consensus:

Dental autoclaves operate within internationally accepted temperature bands proven to kill pathogens.

These ranges balance speed, efficacy, and instrument compatibility.

Avoiding Extremes:

Too low → risks incomplete sterilization.

Too high → damages plastic/rubber components (e.g., handpiece seals).

Gravity Displacement (N-Class):

Uses lower temperatures suited for solid metal tools (e.g., forceps).

Longer cycle times compensate for reduced heat intensity.

Pre-Vacuum (B-Class):

Achieves higher temperatures ideal for hollow instruments and packaged loads.

Shorter cycles due to efficient heat penetration.

Metal Instruments:

Withstand higher temperatures without corrosion or dulling.

Heat-Sensitive Items:

Handpieces, plastic trays, or silicone hoses require gentler heat settings to prevent melting or warping.

Mixed Loads:

Default to the lowest safe temperature protecting the most vulnerable item.

Automatic Calibration:

Built-in sensors adjust temperatures if deviations occur mid-cycle.

Cycle Abort Safeguards:

Machine halts if temperature drops below effective sterilization thresholds.

Chemical Indicators:

Strips on pouches change color only when correct temperature is sustained.

If you have any question for the installation

or need support, please feel free to contact us.

86-15728040705

86-18957491906