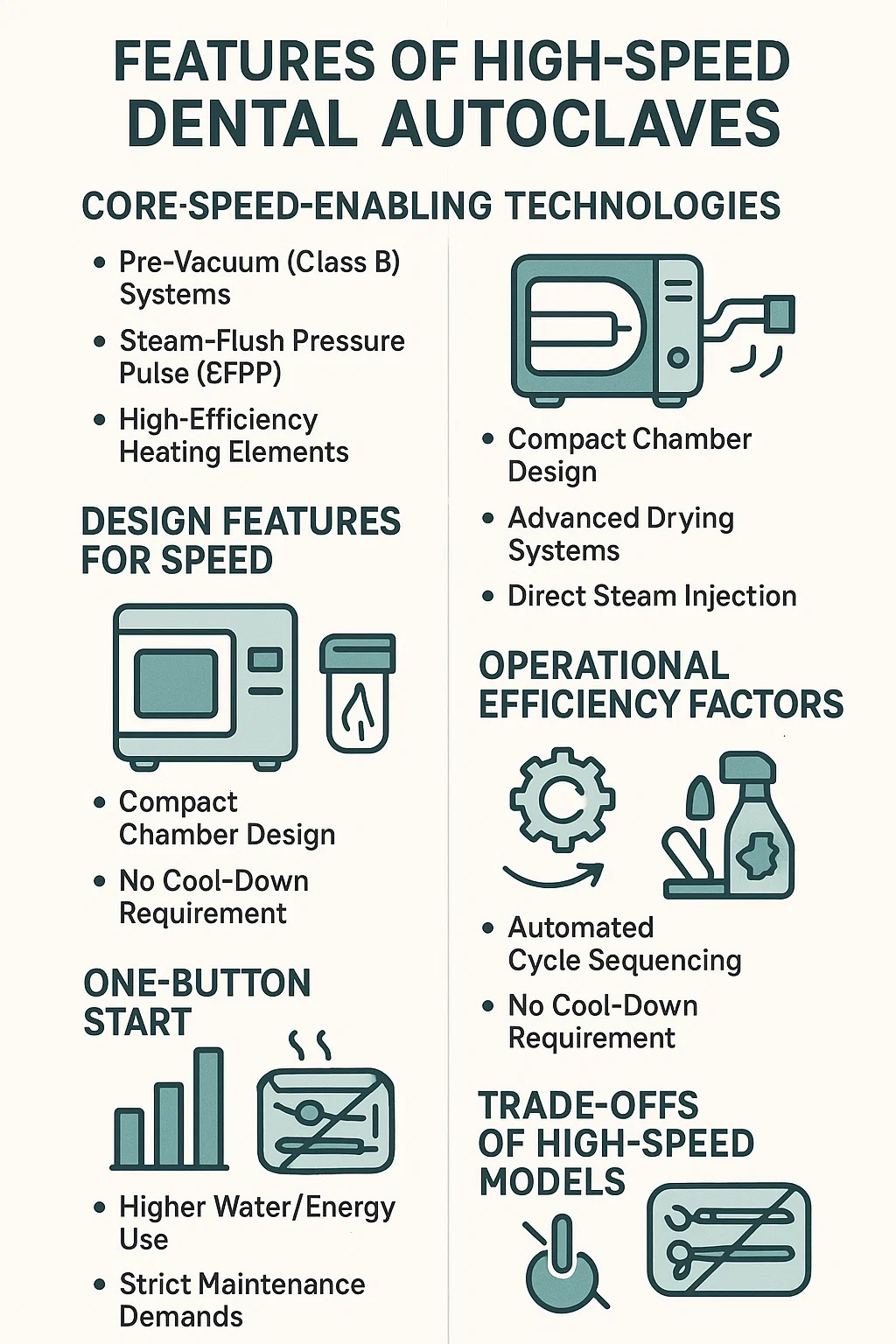

Here's an overview of features that define the fastest dental autoclaves, without referencing brands, models, or technical specs:

1. Core Speed-Enabling Technologies

Pre-Vacuum (Class B) Systems:

Actively remove air with a vacuum pump before steam injection.

Eliminate air pockets instantly, slashing cycle time versus gravity models.

Steam-Flush Pressure Pulse (SFPP):

Blasts steam in rapid pulses to force out air.

Achieves sterilization temperatures faster than passive methods.

High-Efficiency Heating Elements:

Rapidly boil water into steam (under 2 minutes).

Avoid slow "ramp-up" delays.

2. Design Features for Speed

Compact Chamber Design:

Smaller space requires less steam to fill, heating quicker.

Optimized for typical dental instrument loads (not oversized).

Advanced Drying Systems:

Use vacuum-assisted drying to pull moisture from pouches/tools.

Cut drying time by 50%+ vs. passive evaporation.

Direct Steam Injection:

Steam generated externally and injected at high pressure.

Skips chamber heating delays.

3. Operational Efficiency Factors

Automated Cycle Sequencing:

Overlaps heating, sterilization, and drying phases.

No pauses between stages.

No Cool-Down Requirement:

Tools/packs emerge dry and cool-to-touch instantly.

Skip post-cycle waiting periods.

One-Button Start:

Pre-programmed cycles launch in seconds.

4. Trade-Offs of High-Speed Models

Higher Water/Energy Use:

Speed demands intense steam generation.

Requires daily distilled water refills.

Strict Maintenance Demands:

Mineral buildup cripples speed; weekly descaling essential.

Vacuum pumps need quarterly servicing.

Instrument Limitations:

Unsuitable for dense loads (e.g., stacked implant kits).

Hollow tools must be packaged correctly to avoid cycle aborts.

If you have any question for the installation

or need support, please feel free to contact us.

86-15728040705

86-18957491906