Rotary Sealing Machines

-- Steady & Reliable Manufacturer --

Rotary sealing machines represent the high-speed solution for sealing sterilization pouches and reels, essential in high-volume Central Sterile Services Departments (CSSD) and large clinic settings. Unlike constant heat sealers, rotary models utilize continuously moving heated rollers to feed and seal the pouch material. This continuous process dramatically increases throughput, achieving sealing speeds of 8 to 12 meters per minute. They are typically equipped with a precise temperature control system and often an integrated cutting tool to trim the reel material to the required length before sealing. The sealed seam width is consistently uniform and meets strict international standards (e.g., 6mm or 12mm minimum), ensuring reliable sterility maintenance. Rotary sealers also frequently include logging capabilities or external connections to document the sealing temperature and speed, crucial for auditable quality assurance in high-volume regulated environments. Their efficiency and speed are critical for maintaining the rapid turnover of packaged instruments required by busy hospitals.

| | Parameter | Detail |

|---|

| Sealing Mechanism | Continuous Heated Rollers |

| Sealing Speed | 8 to 12 meters per minute (High Throughput) |

| Seam Width | Minimum 6mm (International Standard Compliance) |

| Control System | Microprocessor with Digital Temperature Display |

| Features | Integrated Bi-directional Cutting Tool, Roller Release |

| Data Logging | Optional RS232 Port for Documentation Interface |

| Warm-Up Time | Rapid Heat-Up (Typically < 5 minutes) |

| Material | Corrosion-Resistant Stainless Steel Casing |

Rotary sealing machines are the mandated equipment in all large-scale sterilization environments, including hospital CSSD, large ambulatory surgical centers, and massive dental or medical group practices that process hundreds of instrument packs daily. Their high speed and continuous sealing capability are essential for processing materials from continuous reels, significantly reducing the labor and time required for the packaging phase of instrument reprocessing. They are positioned in the clean packaging zone, where staff prepares instruments for autoclaving. The integrated cutter ensures precise and clean cuts, optimizing material use and reducing waste. Furthermore, the electronic monitoring capabilities make them suitable for facilities requiring ISO 13485 or similar quality management systems, as the sealing parameters can be verified and logged for every batch of instruments. They are instrumental in streamlining the final preparation before sterilization.

Procurement of rotary sealers often involves an initial T/T deposit (30-40%), with the final payment due upon successful factory acceptance testing (FAT) before shipment. L/C at sight is also accepted for large institutional orders. Shipping is facilitated under CIF or DDP terms, utilizing professional crating to protect the delicate roller and heating elements. Due to the precision required, lead times can range from 4 to 8 weeks. We offer specialized training materials and setup guides for integrating the sealer into a high-throughput workflow. Buyers should confirm the required sealing width and whether they need data logging functionality before placing the order. The warranty covers the precision electronic controls and the main drive system. We advise the use of approved, high-quality medical reels designed for rotary sealing to achieve optimal sealing integrity and performance.

The overwhelming advantage of rotary sealing machines is their unparalleled speed and continuous workflow, which eliminates the bottlenecks often created by manual or constant heat sealers in high-volume operations. The continuous, steady pressure of the rollers creates a seal that is highly uniform and robust, minimizing the risk of seal failure during the sterilization cycle or subsequent handling. The integrated cutting feature improves operational efficiency and reduces staff time spent on manually trimming packaging. By ensuring that instrument packs have a consistently high-quality, auditable seal, the rotary sealer contributes directly to assured sterile shelf life, enhancing patient safety and reducing liability for the healthcare provider. The robust, industrial design allows for long-term, continuous operation with minimal required maintenance, ensuring high uptime for a mission-critical function.

- Q: What kind of pouches or reels can a rotary sealer use?

- A: Rotary sealers are primarily designed to work with lay-flat or gusseted **sterilization reels** (rolls of paper/film) that are cut to custom lengths, although they can seal pre-cut pouches as well.

- Q: How do I maintain the rotary rollers?

- A: The rollers should be cleaned daily to remove any adhesive residue or ink using a manufacturer-approved solvent. Regular inspection for wear and tear on the silicone/Teflon coating is necessary to ensure a perfect seal.

- Q: Can the sealing temperature be adjusted?

- A: Yes. Modern rotary sealers feature precise digital temperature control, allowing the operator to adjust the temperature to match the specific requirements of different sterilization reel/pouch materials and thicknesses.

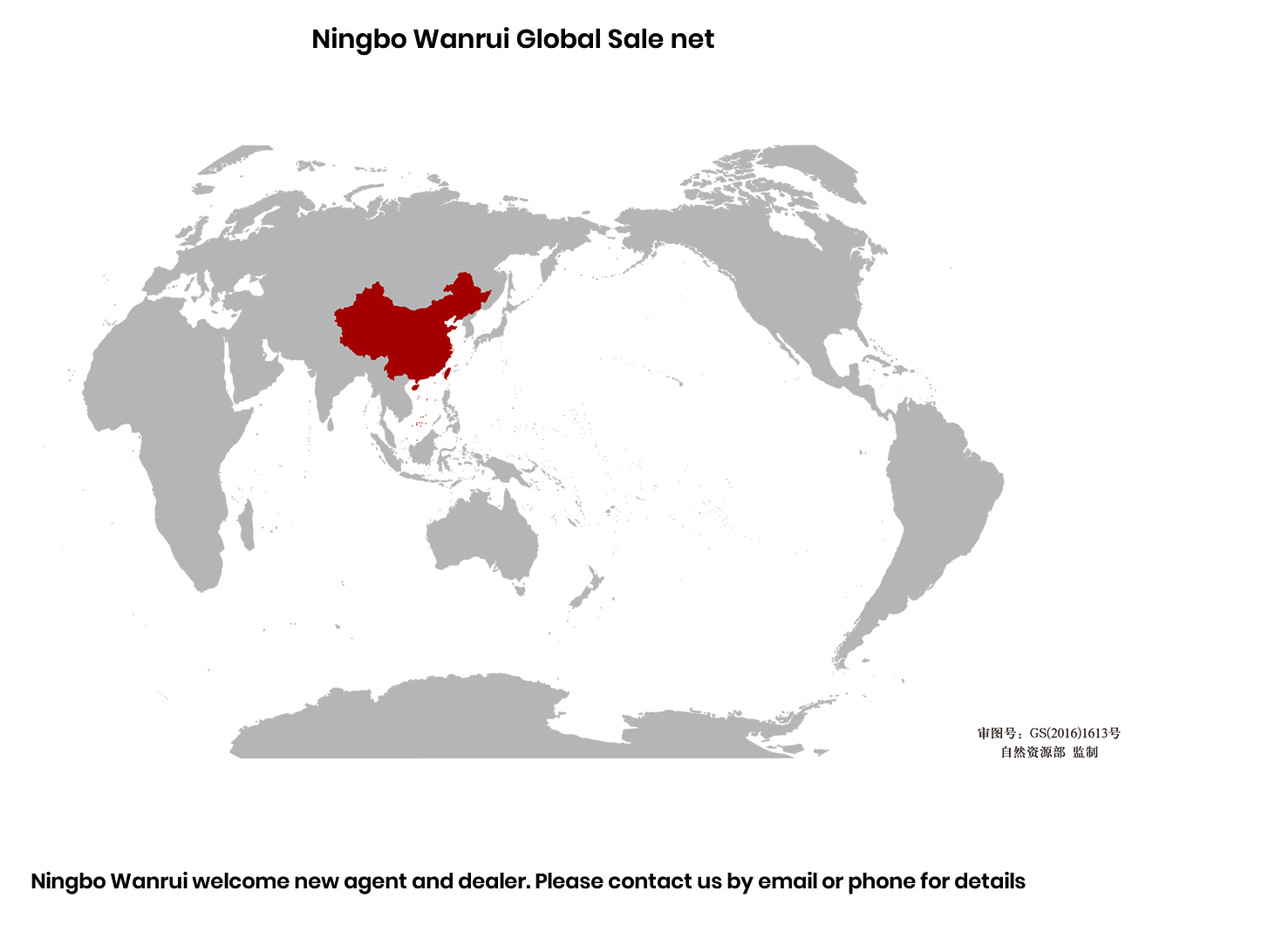

Wanrui Medical Instrument

Our products are mainly exported to over 30 countries such as USA,Germany,Japan,Spain,Italy,UK,Korea,Australia,Canada,Iraq,Algeria and etc.

Ningbo Wanrui obtains customer's trust through honesty and sincerity, and redounds

on customers by superior quality & high-tech product. We commit our selves to

making friends both in China and oversea by our exceptional products and complete service

service! "Keep improving, serve our customers" is our goal, we sincerely look

forward to cooperating with you!

English

English عربى

عربى