Product character * based on the new class B,have 3pulsating vacuum,vacuum up to -0.8Bar. ...

Product character *based on the new class B,have 3pulsating vacuum,vacuum up to -0.8Bar. *P...

Product character * based on the new class B,have 3pulsating vacuum,vacuum up to -0.8Bar. ...

Product character *based on the new class B,have 3pulsating vacuum,vacuum up to -0.8Bar. *P...

Product character *Class N type *Fully automatic *Led display *Over heat protection *Pressure overlo...

*Friendly reminder:purified water is not distilled water. *Autoclave must adopt distilled water as ...

A water distiller is essentially a small factory dedicated to producing "pure water." In dental clinics, it's ...

A portable dental autoclave is a smaller, lighter, mobile autoclave. If a large autoclave is like a large refr...

The validation of a dental autoclave, simply put, is to provide a "double guarantee" for the sterilization eff...

Although the sterilization equipment used in dental clinics may look similar, these dental autoclaves are typi...

Dental autoclaves, in simple terms, work like an upgraded version of a household pressure cooker. They utiliz...

For dental clinics, there isn't one single "world's best" model, but the generally accepted best choice usuall...

The pressure in a dental autoclave is a critical factor in the steam sterilization process, working in conjunc...

Here's a practical guide to sterilizing dental burs using an autoclave: Prep Work Before Sterilization Clean...

If you have any question for the installation

or need support, please feel free to contact us.

86-15728040705

86-18957491906

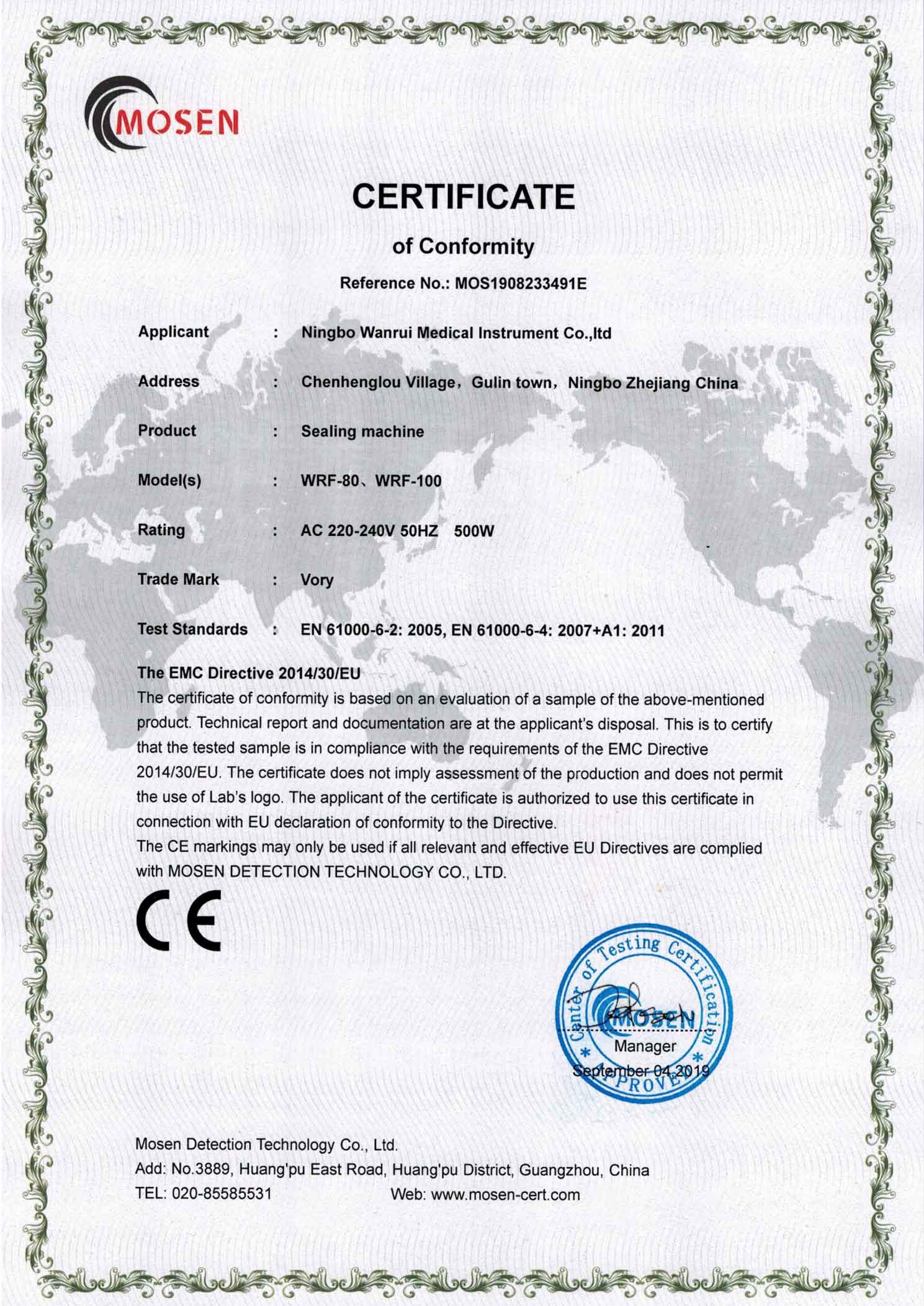

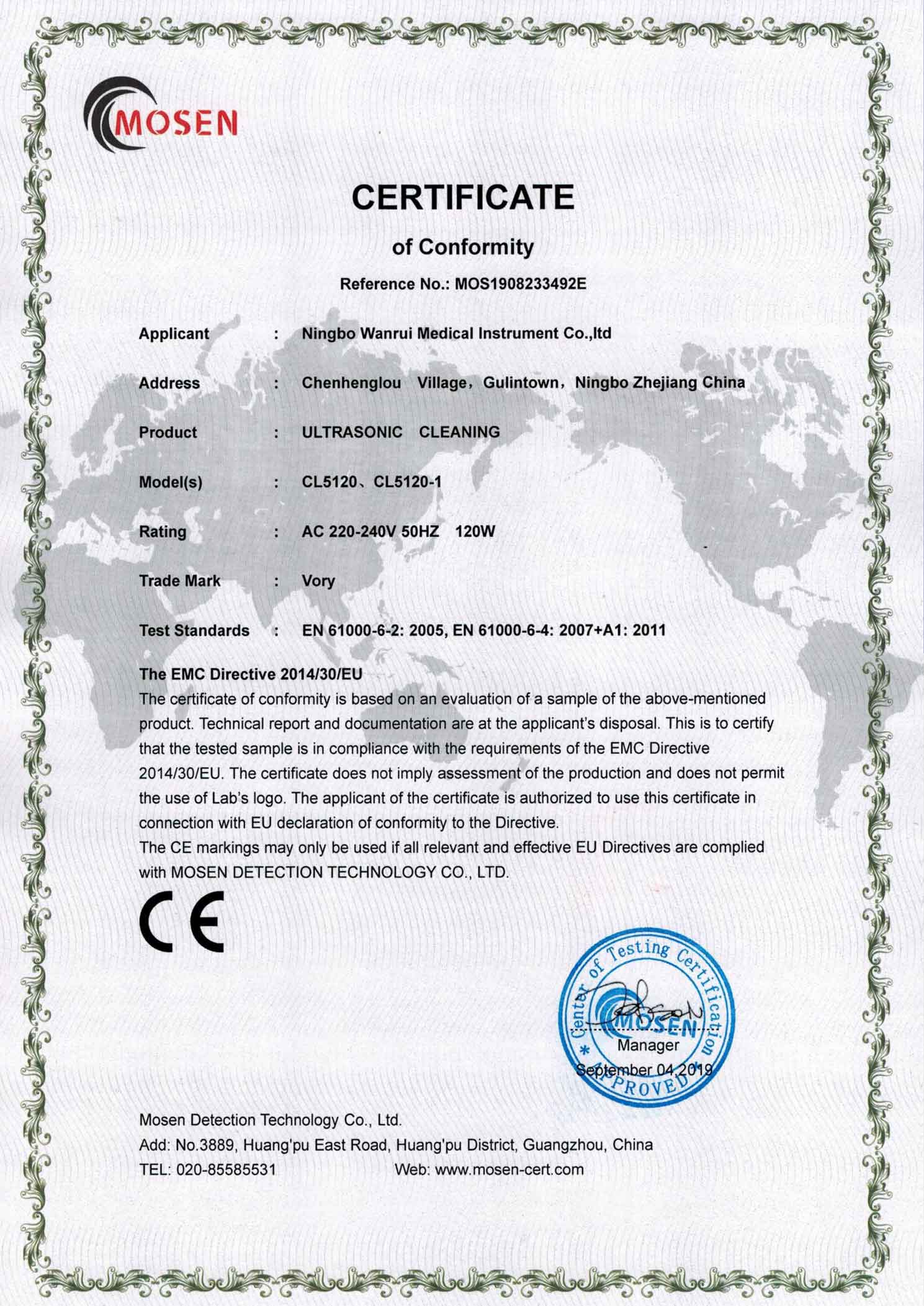

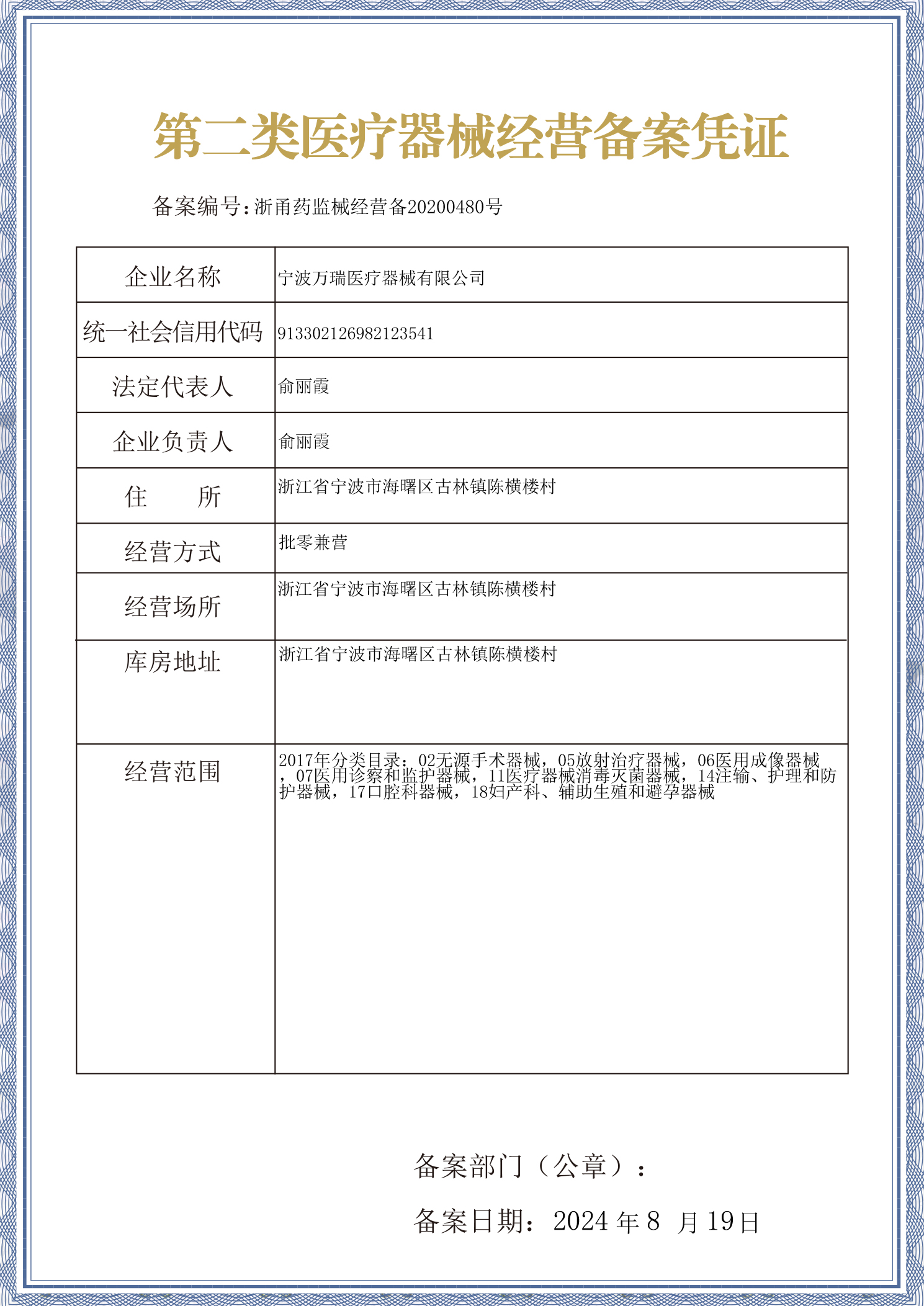

In the dental field, sterilization equipment plays a vital role, ensuring instrument sterility and patient safety. As a trusted partner in the industry, Ningbo Wanrui Medical Instrument Co., Ltd. consistently adheres to integrity and responds to customer needs by providing high-quality, high-tech products. The company understands that core equipment knowledge not only improves diagnostic and treatment efficiency but also lays the foundation for medical quality.

Question: What is the main function of a dental autoclave sterilizer?

Answer: Dental autoclave sterilizers are designed specifically for dental clinics. Their core purpose is to eliminate microbial contamination, including bacteria, viruses, and spores, from instrument surfaces. These devices utilize a high-pressure steam environment to achieve thorough sterilization, ensuring that treatment instruments are sterile before each use. Ningbo Wanrui Medical Instrument Co., Ltd. is dedicated to this area, developing high-tech solutions that ensure easy operation and stable performance, helping dental professionals maintain stringent infection control standards. The company's product line reflects its commitment to high-quality output, and each sterilizer is designed to seamlessly integrate into daily clinical practice, reducing the risk of cross-infection.

Question: What are the key steps involved in the working principle of a dental autoclave sterilizer?

Answer: The core mechanism of the device relies on the application of high-pressure saturated steam, which is divided into three stages: pre-vacuum, sterilization, and drying. During the pre-vacuum stage, air is removed from the sterilization chamber to prevent residual air from interfering with steam penetration. Subsequently, high-temperature, high-pressure steam is injected, penetrating the instrument surface and destroying the protein structure of microorganisms. Finally, the drying stage removes excess moisture, ensuring that the instruments are ready for use upon removal. Ningbo Wanrui Medical Instrument Co., Ltd.'s sterilizers incorporate advanced control systems to optimize these processes and ensure efficient operation. The company emphasizes integrity in its operations and implements strict quality control to ensure that the equipment maintains consistency under high-pressure conditions, avoid potential malfunctions, and enhance operational reliability in dental clinics.

Question: Why are dental autoclave sterilizers essential for infection control?

Answer: Dental treatment involves frequent instrument contact. Incomplete sterilization can easily lead to cross-infection or nosocomial transmission. Autoclaves provide a physical sterilization method that is more thorough, environmentally friendly, and carries no residual risk compared to chemical disinfection. They can process a wide range of instruments, including metal tools and heat-resistant materials, meeting the broad needs of dental practices. Ningbo Wanrui Medical Instrument Co., Ltd.'s products leverage this core strength, manufactured with high-standard materials to enhance equipment durability and sterilization effectiveness. Through continuous innovation, the company has introduced intelligent monitoring features that allow users to track the sterilization process in real time. This reflects its commitment to rewarding customers with high technology and helps clinics build a strong defense against infection.

Question: What are the main advantages of dental autoclave sterilizers?

Answer: These advantages encompass efficiency, reliability, and user-friendliness. The equipment can complete sterilization cycles in a short time, shortening instrument turnaround time and optimizing clinic workflow. Furthermore, its design prioritizes safety, with multiple safeguards to prevent operational errors. Modern sterilizers also emphasize compatibility, accommodating dental kits or trays of varying sizes. Ningbo Wanrui Medical Instrument Co., Ltd. incorporates user-friendly elements into its R&D to ensure easy maintenance and cleaning of its equipment, reducing the burden of daily management. Driven by integrity, the company is committed to providing durable products with extended service life. Through professional support services, we help users maximize the value of the equipment, ultimately enhancing the overall clinical experience.

Question: What are the key points to consider when maintaining a dental autoclave sterilizer?

Answer: Maintenance is key to ensuring the long-term performance of the equipment and involves regular cleaning, component inspection, and calibration. Users must ensure water quality is pure to avoid mineral deposits that could affect steam generation. Consumable parts such as seals and valves should be replaced promptly to maintain the integrity of the high-pressure environment. Ningbo Wanrui Medical Instrument Co., Ltd. recommends a preventative maintenance strategy. Its product design simplifies maintenance procedures, with built-in self-diagnosis features to quickly identify potential issues. The company's high-quality service network provides targeted guidance, enhancing equipment reliability. This attention to detail stems from the company's culture of integrity – a commitment to transparently support customers and ensure a flawless sterilization process.

Question: How do dental autoclave sterilizers adapt to modern dental technology?

Answer: With the diversification of dental instruments and the prevalence of minimally invasive procedures, sterilizers need to be flexible enough to handle delicate tools while integrating digital trends such as data logging and remote monitoring. Equipment is evolving towards intelligence, enhancing sterilization accuracy and traceability. Ningbo Wanrui Medical Instrument Co., Ltd. actively embraces innovation, developing products that integrate IoT technology and allow users to optimize settings through a simple interface. The company's high-tech investments not only respond to industry changes but also demonstrate its customer-centric values—empowering dental advancements and strengthening bonds of trust through reliable equipment. This forward-thinking approach ensures that sterilization solutions remain at the forefront of the industry.